Everybody has probably seen the bright sign with the letters Ex some time, but what does it mean?

ATEX is an acronym derived from the French sentence Appareils Destinés à être utilisés en ATmosphères EXplosibles and is common name for two EU directives that regulate how organisations should manage potentially explosive environments. Many workplaces may contain or generate explosive environments due to flammable substances being present or introduced in the air. This is common at, for instance petrochemical industries, paint workshops, mines and even some organic flour producers.

If a sufficient amount of air gets mixed with an ignitable substance like combustible gas, mist, steam or dust a single ignition source can cause an explosion, with potentially disastrous consequence. Preventing the occurrence of hazardous substances and eliminating ignition sources are two highly effective and widely used methods to minimize the risk and, are also the basis for the ATEX directives.

The workplace directive

Directive 99/92/Ex or ATEX 137 regulate the minimum requirements that employers must meet in order to improve safety for workers in exposed environments. In essence it requires employers to identify all potentially explosive atmospheres. These spaces then need to be systematically evaluated and classified with regard to,

- The hazardous properties of the substances present.

- The amount of substances.

- All affected processes and their exposure to the substances.

- At what temperatures and pressures the substances are handled.

- The containment system and possibilities to prevent unwanted leaks.

- Measures available to prevent explosive environments to persist for long periods (i.e. ventilation).

Zone classifications for gas, mists and vapours;

Zone 0

Environment where a mixture of air and flammable s gas, mist or vapour occurs often and persists for long periods of time.

Zone 1

Environment where a mixture of air and flammable gas, mist or vapour is likely to occur under normal conditions.

Zone 2

Environment where a mixture of air and flammable gas, mist or vapour can occur under normal conditions but dilutes quickly.

Zone classifications for dust;

Zone 20

Environment where explosive clouds of dust appear often and for extended periods.

Zone 21

Environment where explosive clouds of dust can appear under normal conditions.

Zone 22

Environment where explosive clouds are not likely to appear and if they do, they disappear quickly.

Depending on the classification (level of risk) different guidelines shall be followed to ensure worker safety. These guidelines can comprise of establishing specific routines, placing warning signs, providing anti-static clothing and/or equipping them with the right type of intrinsically safe devices and safety equipment.

The equipment directive

Directive 94/9/EC, also known as ATEX 95 consists of requirements on all devices and safety equipment intended for use in potentially explosive environments. The objective with the directives are to enable fair competition with ATEX devices and safety equipment by regulating terms, testing and documentation of such material within the EU.

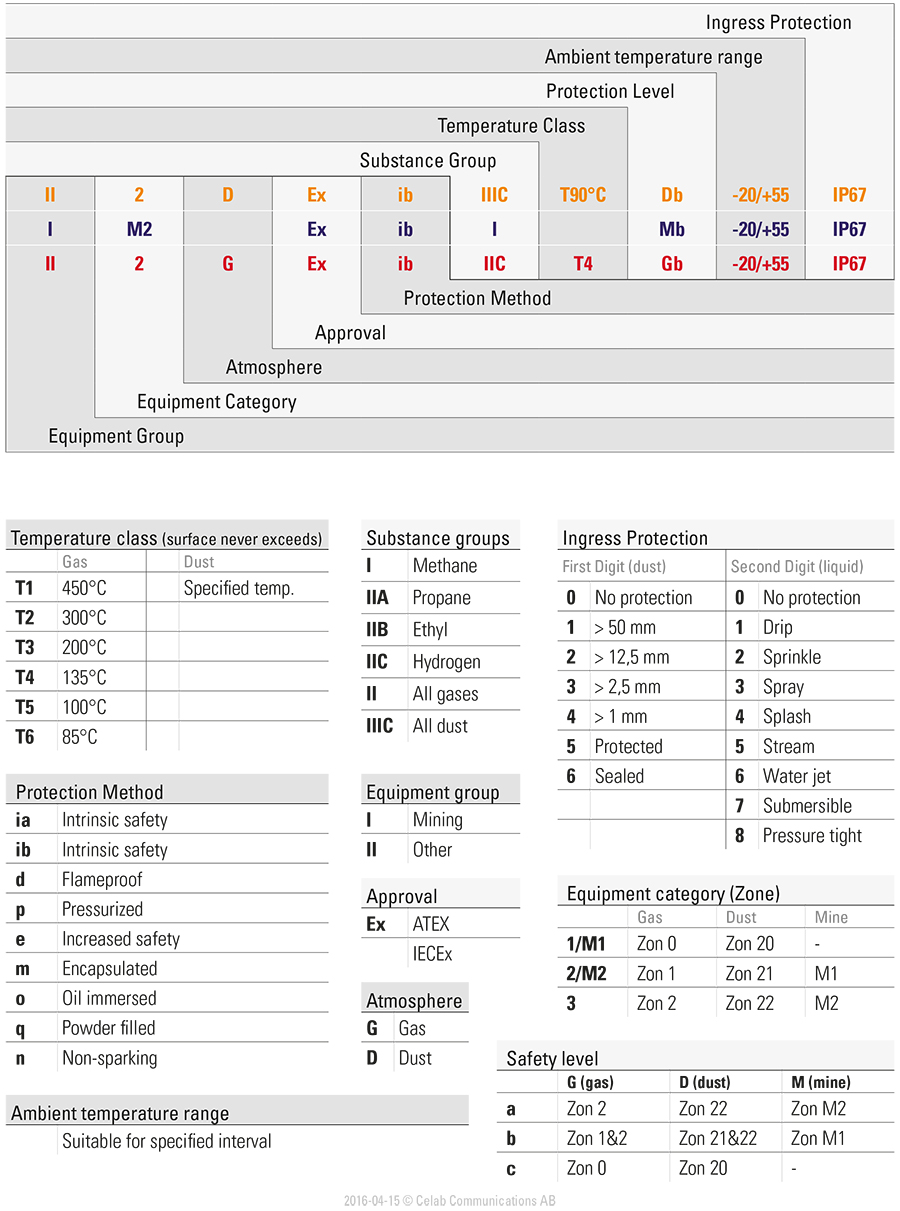

Manufacturers and importers must ensure that their products meet specific requirements and undergo appropriate external certification processes. This declaration of conformity guarantees that the equipment is suitable for its intended use and gives besides right to bear the EX mark also classifications code that specifies in which environments the device is approved for use.

II 2G Ex ib IIC T4 Gb -20°C/+55°C IP65/66/67

Gas classification for Motorola MTP8550Ex

II 2D Ex ib IIIC T90°C Db -20°C/+55°C IP65/IP66/IP67

Dust classification for Motorola MTP8550Ex

I M2 Ex ib I Mb -20°C/+55°C IP65/IP66/IP67

Mining classification for Motorola MTP8550Ex